This article shows how to interface a DC

motor to an 8051 microcontroller. Interfacing DC motor to 8051 forms an

essential part in designing embedded robotic projects. A well designed

8051-DC motor system has essentially two parts. Firstly an 8051 with

the required software to control the motor and secondly a suitable

driver circuit. Most of the DC motors have power requirements well out

of the reach of a microcontroller and more over the voltage spikes

produced while reversing the direction of rotation could easily damage

the microcontroller. So it is not wise to connect a DC motor directly to

the microcontroller. The perfect solution is to use a motor driver

circuit in between the microcontroller and the DC motor.

L293 motor driver.

L293 is a dedicated quadruple half H

bridge motor driver IC available in 16 pin package. To know more about H

bridge, check this link. H bridge motor driver circuit .

L293 has a current capacity of 600mA/channel and has supply voltage

range from 4.5 to 36V DC. They are fitted with internal high speed clamp

diodes for inductive spike protection. Other good features of L293 are

high noise immunity, internal ESD protection, thermal shutdown, separate

input supply for each channel etc. The pinout and truth table of an

L293 motor driver is shown in the figure below.

|

| L293 pinout and function diagram |

Bi directional DC motor using 8051.

This project describes a bidirectional

DC motor that changes its direction automatically after a preset amount

of time (around 1S). AT89S51 is the microcontroller used here and L293

forms the motor driver. Circuit diagram is shown below.

|

| Bi directional DC motor using 8051 |

In the circuit components R1, S1 and C3

forms a debouncing reset circuitry. C1, C2 and X1 are related to the

oscillator. Port pins P1.0 and P1.1 are connected to the corresponding

input pins of the L293 motor driver. The motor is connected across

output pins 3 and 6 of the L293. The software is so written that the

logic combinations of P1.0 and P1.1 controls the direction of the

motor. Initially when power is switched ON, P1.0 will be high and P1.1

will be low. This condition is maintained for a preset amount of time

(around 1S) and for this time the motor will be running in the clockwise

direction (refer the function table of L293). Then the logic of P1.0

and P1.1 are swapped and this condition is also maintained for the same

duration . This makes the motor to run in the anti clockwise direction

for the same duration and the entire cycle is repeated.

Program.

ORG 00H // initial starting address

MAIN: MOV P1,#00000001B // motor runs clockwise

ACALL DELAY // calls the 1S DELAY

MOV P1,#00000010B // motor runs anti clockwise

ACALL DELAY // calls the 1S DELAY

SJMP MAIN // jumps to label MAIN for repaeting the cycle

DELAY: MOV R4,#0FH

WAIT1: MOV R3,#00H

WAIT2: MOV R2,#00H

WAIT3: DJNZ R2,WAIT3

DJNZ R3,WAIT2

DJNZ R4,WAIT1

RET

ENDBidirectional motor with pushbutton control.

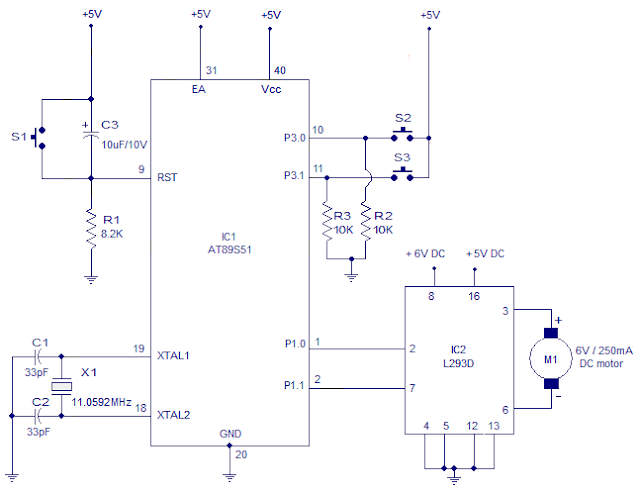

The circuit shown below is of an 8051

based bi directional motor whose direction can be controlled using 2

push button switches. The circuit is very similar to the previous one

except for the two push button switches . These pushbutton switches

are interfaced to P0rt 3 of the microcontroller. Resistors R2 and R3

are the pull down resistors for P3.0 and 3.1 respectively.

| |

| Push button controlled bi-directional DC motor |

The code for the above project is so

written that initially when power is switched ON, the motor remains OFF.

When push button switch S2 is pressed P1.0 goes high and P1.1 remains

low. The motor runs in the clockwise direction and this condition is

maintained until S3 is pressed. When push button switch S3 is pressed

the logic of P1.0 and P1.1 toggles making the motor to run in the

opposite direction and this condition is maintained until the next press

of S2.

Program.

ORG 00H // initiall starting address

MOV P3,#00000000B // initiates P3 as the pushbutton interface

MOV P1,#00000000B // clears P1 for keeping the motor OFF initially

MAIN:MOV A,P3 // moves the current state of P3 to Accumulator

CJNE A,#00000001B,LABEL1 // checks whether S2 is pressed

MOV P1,#00000001B // makes the motor run clockwise

LABEL1:CJNE A,#00000010B,LABEL2 // checks whether S3 is pressed

MOV P1,#00000010B // makes the motor to run anti clockwise

LABEL2:SJMP MAIN // jumps back to the MAIN loop

ENDAbout the program.

Checking whether a particular push

button is pressed is done using the CJNE (compare and jump if not equal)

instruction. In simple words the CJNE instuction compares two operands

and jump to a predefined LABEL if the operands are not equal. If the

two operands are equal nothing happens and the next instruction is

executed. Whenever push button S2 is pressed the status of P3 will be

00000001B .This status is moved to accumulator A and compared with

00000001B using the CJNE instruction. Both operands are equal means S2

is pressed and the next instruction (MOV P1,#00000001B) which makes the

motor run clockwise is executed. If the operands are not equal that

means the S2 is not pressed and the controller jumps to LABEL1 which is

to check the S3. To check S3, status of P3 is moved to A again and it

is compared with 00000010B using the CJNE instruction. Both operands are

equal means the S3 is pressed and the next instruction

(MOV P1,#00000010B) which makes the motor run anti clockwise is

executed. Both operands are not equal means S3 is not pressed and the

controller goes to check S2 again and this cycle is repeated.

Notes.

The maximum current capacity of L293 is 600mA/channel. So do not use a motor that consumes more than that.The supply voltage range of L293 is between 4.5 and 36V DC. So you can use a motor falling in that range.

No comments:

Post a Comment